The contract calls for the supply and installation of a treatment unit designed to treat and neutralize wastewater from the mortuary. The process used will be chemical, based on the action of sodium hydroxide NaOH. It is imperative that all effluent from the autopsy room, and in principle from all points where liquid discharges are likely to be contaminated, particularly with ATNC, be treated. These discharges are loaded with organic matter. ATNC inactivation in accordance with DGS/DH directive no. 138 will be carried out in a treatment unit.

The process implemented will be chemical, based on the principle of the action of sodium hydroxide (NAOH). To ensure effluent neutralization, and in particular the inactivation of ATNCs, in compliance with legislation, the contact time will be a minimum of 1 hour at PH 12.2, followed by neutralization of the chemically active effluent with acid to bring the pH down to a value between 6.5 and 7.5, enabling it to be discharged into the urban network. All effluent coming from the technical room will be stored in the treatment unit during the day, to undergo neutralization treatment in the evening.

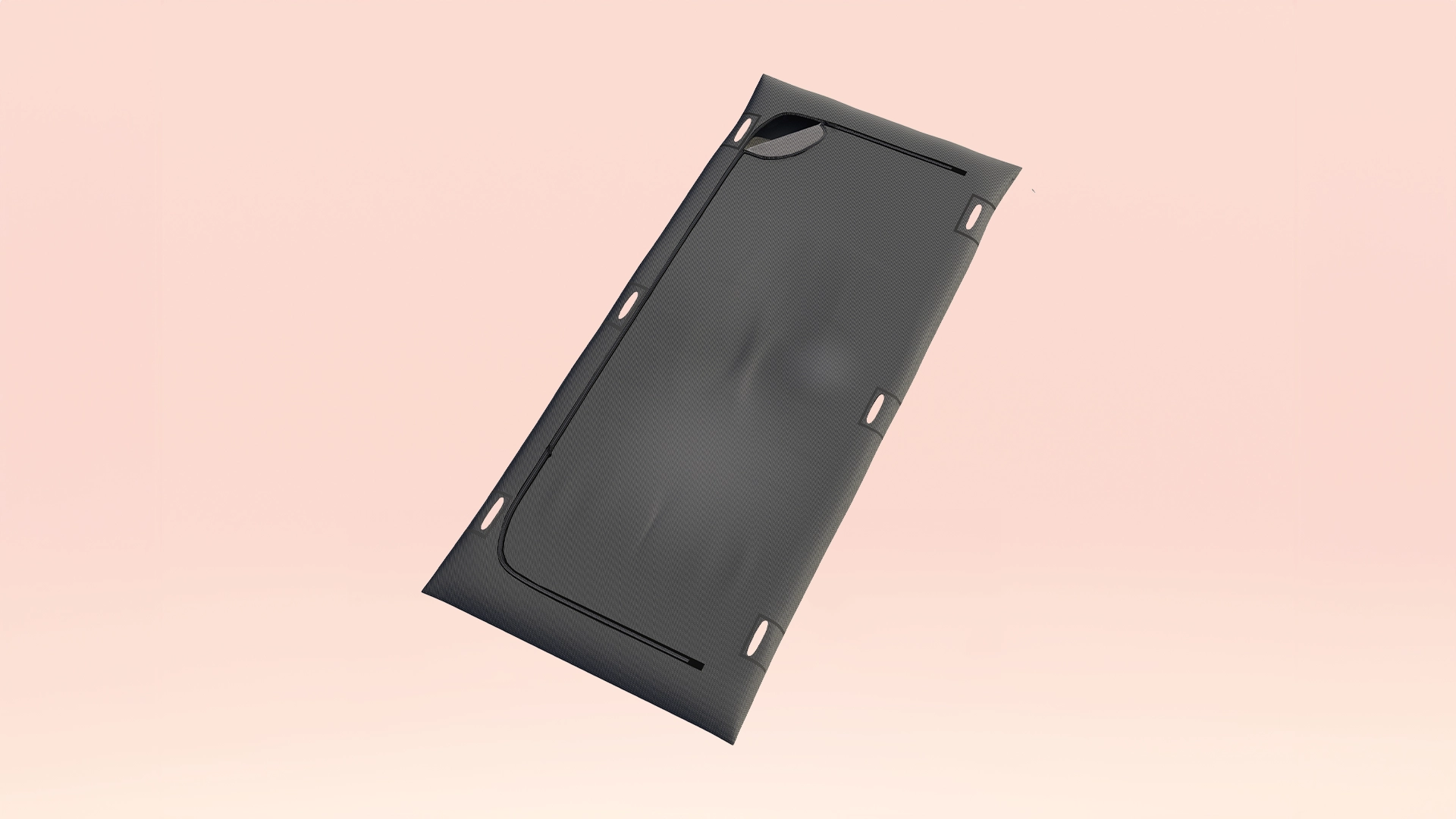

1) Storage and homogenization tank: in HDPE (High Density Polyethylene), double-skinned, with a volume of 2000 liters, equipped with : 1 manhole with cover, 1 effluent inlet port, 1 effluent outlet port, 1 ventilation port fitted with a charcoal filter or to be connected to the building’s secondary ventilation system. 3 level regulators, 1 agitator, 2 overhead lifting pumps, 1 stainless steel support for pumps and agitator.

2) Treatment tank: HDPE, double-skinned, 2000-liter volume, equipped with : 1 manhole with cover, 1 effluent inlet, 1 effluent outlet, 1 ventilation port fitted with a carbon filter or to be connected to the building’s secondary ventilation system, 3 level regulators, 1 agitator, 2 overhead lift pumps, 1 stainless steel support for pumps and agitator, 2 connections for soda and acid injection, 1 connection for pH probe.

3) Neutralization unit and acid-base pH regulator: 1 soda metering pump, 1 acid metering pump, 1 pH regulator, 1 pH probe, 1 electrical control cabinet for all equipment, 2 20-liter (27 kg) acid drums, 2 20-liter (27 kg) soda drums, 2 retention tanks.

4) Electrical control cabinet: Electrical control cabinet for the treatment unit with alarm reporting.

Option: Plug and Play installed in a 20′ container.

Treatment unit for treating and neutralizing wastewater from mortuary or autopsy services

The contract calls for the supply and installation of a treatment unit designed to treat and neutralize wastewater from the mortuary. The process used will be chemical, based on the action of sodium hydroxide NaOH. It is imperative that all effluent from the autopsy room, and in princip...

+ More about this productDescription

Packaging:

in individual cardboard boxes.